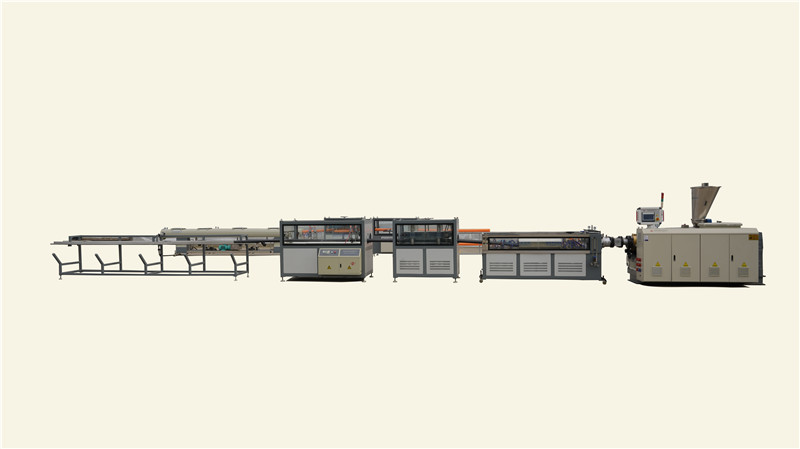

PE Optical Cable Micro-Duct Bundles machine

HDPE PE Optical Cable Micro-Duct Bundles Coating Jacketed Tube Pipe Machine

HDPE Communication Tube A Bundle Pipe Make Machine / Extrusion Line

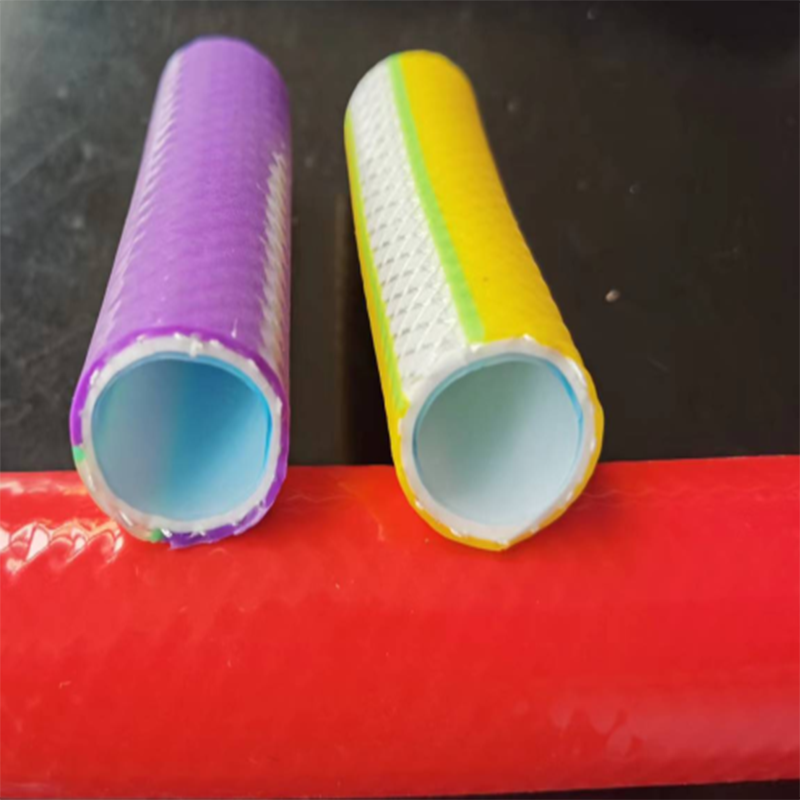

ʻElua ʻōnaehana ʻo ka mīkini paipu HDPE Communication, hoʻokahi ʻo HDPE microduct tube extrusion line, hoʻokahi ʻo HDPE communication bundle pipe extrusion line.A ʻo ka paipu puʻupuʻu paha he paipu hoʻoheheʻe ʻia (COD pipe) a i ʻole ʻōnaehana paipu polygon.

Ka papa inoa o nā lako mīkini:

1. Pūnaehana paipu kumu: Mea hānai 'akomi, SJ65/33 Extruder.SJ25/25 Markline extruder, Make paipu kumu, pahu pahu, pahu wai, mīkini huki, coiler

2. Pūnaehana Paipu Pupu: Uncoiler no ka paipu kumu, mea alakaʻi, uhi make, 65/33 Extruder, Vacuum tank, haul off machine, coiler

1. Hookahi Screw Extruder

Aia he 45/33,65/30,65/33,75/30,75/33, 90/33... etc extruders e like me diameters a me ouput.

ʻO ka mana kiʻekiʻe o ka extrusion ma ke kumu kiʻekiʻe.ʻO ka hoʻolālā plasticizing haʻahaʻa haʻahaʻa, e hōʻoia i ka extrusion paipu kiʻekiʻe.Mea o ka wili a me ka barela: 38CrMoAlA, nitrogen kinai (0.4-0.7mm), Rigidity o ka wili:>740, rigidity o ka barela>940, ka ili o ka wili ua chromeplated ka nahele hānai me ka wai hooluolu.

Hoʻohana ka uila o ka mīkini i nā ʻāpana ABB, Siemens, Omron a me Schneider, ka hana paʻa a me ke ola lawelawe lōʻihi.

Ke hoʻohana nei nā extruders i ka mīkini kiʻekiʻe kiʻekiʻe, ʻo kāna L / D ʻo 33: 1, ua hoʻolako ʻia me kahi kaʻa kiʻekiʻe-torque a loaʻa ka hana kiʻekiʻe.

2. Pipe Extrusion Die poo

Hana ʻia ke poʻo make e 40Cr molds material.

Ke hoʻohana nei i ke ala wela mika

Hiki ke hana i ka uhi me 2 ala, 3way, 4way, 5way, 7way etc.

3. Paipu wai pahu

Hoʻohana ʻia ʻo ia i nā mea kila kila, kiʻekiʻe kiʻekiʻe a me ka pumb wai.Aia ka ʻōnaehana hoʻopaʻa kahe no ka maikaʻi o ka ʻili paipu.

ʻO ka pahu calibration vacuum a me ka pahu hoʻoluʻu he kila kila, hoʻohana mākou i nā ʻōpala a me nā paila kiʻekiʻe, me ka neʻe ʻana o nā kaʻa ma lalo o ka mīkini no ka hana maʻalahi.

E like me nā kikoʻī o nā paipu hiki ke koho ʻia i kahi lumi hoʻokahi a i ʻole ka hoʻolālā lumi ʻelua o ka pahu pahu;-

ʻO SUS304 ka pahu pahu hao hao a me ka pipeline me ke ola lōʻihi o ka lawelawe ʻana; Ka mālama ʻana i ka mahana kūpono a me ka mālama ʻana i ka pae wai; ʻO ka nui o nā kānana wai a me ka hoʻokaʻawale ʻana; a me ka walaʻau; ʻO ka lima nui i hana ʻia i nā mea kiʻekiʻe

e like me ke keleawe keleawe a me ke kila kuhiliʻole e koho ponoʻia e hōʻoia i ka hoʻokele wela maikaʻi a me ka hopena hoʻomaha maikaʻi.ʻO ke ʻano kiʻiʻoniʻoni wai, ʻano disc, ʻano maloʻo a me nā hoʻolālā hoʻolālā ʻē aʻe i kūpono no ka wikiwiki kiʻekiʻe, kiʻekiʻe-volume extrusion o nā ʻano paipu maka.

4.Haul off unit

Hiki iā ia ke kāʻei ʻōpala a i ʻole ke ala hoʻopaʻa paʻa.

PVC HDPE PE PPR Plastic Profile a me Pipes Caterpillar Haul off Machine

Noi:

Hoʻohana ʻia ke ʻano kaha kiʻi ʻano ʻano ʻano ehe CS, ʻo ke kiaʻāina stepless thyristor.

Hoʻohana nui ʻia me kahi extruder plastik no nā mea paipu plastik, paipu palupalu a me nā mea ʻano ʻano plastik ʻē aʻe.He ākea kona hoʻohana a maʻalahi kona hoʻohana.

| Hoʻohālike | CS1 | CS2 | CS3 |

| Ka māmā kaha kaha: m/min | 1-10 | 0.5-0.5 | 0.5-2 |

| kiʻekiʻe kaha kiʻi | 950-1100 | 950-1100 | 950-1100 |

| Mana kaha kiʻi | 2.2 | 4 | 5.5 |

| Nui hiʻona | 1800x885x1720 | 2800x1015x1720 | 3200x1300x1750 |

5. Mīkini wili

Hoʻohana ʻo ia i ka ʻāpana kaʻa kaʻa kaʻa, max winding 1km a 5km e like me ke noi o ka mea kūʻai aku

Hoʻohana nui ʻia ka mīkini i ka wili ʻana a me ka hoʻopili ʻana i nā paipu plastik maʻalahi, e like me: HDPE, nā paipu LDPE, nā paipu PVC palupalu a pēlā aku.

ʻO ka hoʻololi ʻana i ka wikiwiki a me ka wili ʻana e ka motor torque;i ka paipu extruding wikiwiki lohi, wili 'akomi lohi i lalo e malama like torque;i ka paipu wikiwiki, wili ʻakomi wikiwiki e mālama i ka torque like.

Loaʻa iā Winder kahi mea hoʻopaʻa paʻa, ʻaʻole ikaika ka pneumatic cylinder i ka wā wili, hiki i kēia ke hoʻomaikaʻi i ke ola o ka cylinder, a ʻoi aku ka kiʻekiʻe o ka palekana, ʻo ka ʻōwili paipu hoʻokuʻu ʻana, ʻaʻohe pono e huki i ka ʻōwili paipu ma ka lima.