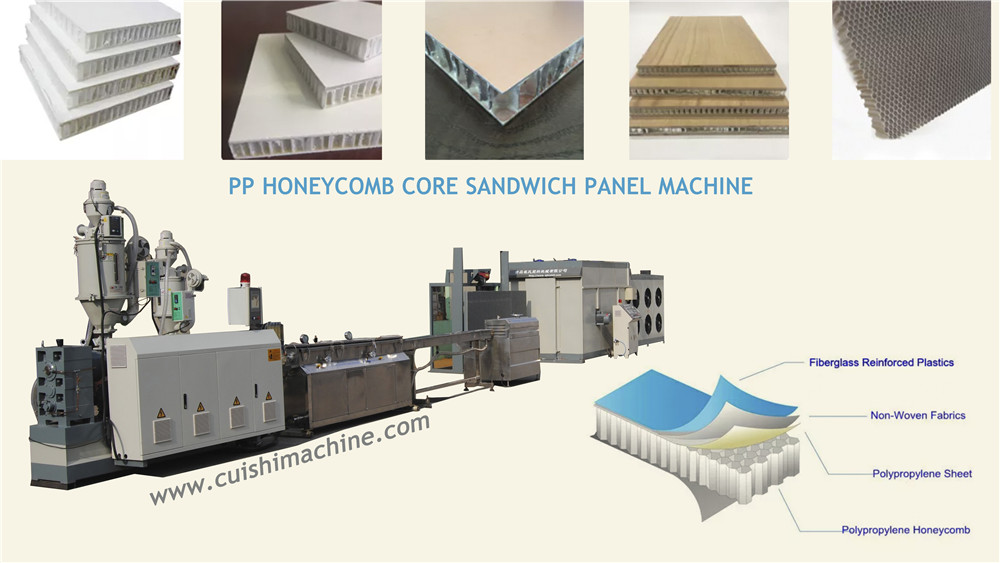

Pp Construction Template Extruder Machine / PP Hollow Sheet Board Construction Formwork Building Template Extrusion Line

ʻO ka mīkini hollow pp pepa extrusion mīkini PP kūkulu hale papa extrusion laina PP pahu pahu extrusion mīkini laina

ʻO ka papa hana hoʻohālike PP extrusion line plastic formwork papa hana mīkini

Hiki i ka laina hana ke hoʻohana i nā mea waiwai PP a hoʻohana i kahi extruder hoʻokahi-screw e hana i nā ʻāpana ʻekolu.ʻO ka maikaʻi a me nā kiko'ī o nā papa i hanaʻia e kūpono i nā koi o ka hui koi.He huahana hou ka pa'i pa'i ma hope o ka hana lā'au, ke kila huila, ka mea ho'opa'a lā'au 'ohe a me ka hana hao nui.ʻO ka hollow plastic formwork ka mālama ʻana i ka ikehu a me ka mālama ʻana i ke kaiapuni, a hiki ke hoʻololi piha i ka formwork kila kuʻuna, formwork lāʻau, lāʻau square, He aha hou aku, he haʻahaʻa loa kona kumukūʻai amortization.

ʻO ka papa hoʻohālike PP Plastic Construction i kapa ʻia ʻo PP hollow form-work

1) Ka mea i hana ʻia me ka pauka PP i hoʻololi ʻia me nā mea hoʻohui ʻē aʻe e ka hoʻomehana a me ka extruding.

2) He mau manawa hoʻohana kiʻekiʻe a me ka hōʻoia wai

3) Hiki ke pani i ka lāʻau plywood maʻamau.Eco-friendly a maʻalahi hoʻi e hui.

4)Plastic Construction Form-ʻo ia ke ʻano o ke kūkulu ʻana i nā hale paʻa me nā mea hoʻohana hou.ʻAʻole pono kēia ʻano hana i nā mākau hana, hoʻokō i ka hana i ka manawa hoʻopaʻa, me ka liʻiliʻi liʻiliʻi o ke kaʻina hana.

Papa inoa mīkini (PP Hollow Sheet Board Construction Formwork Building Template Extrusion Line Single Screw Plastic Extruder Machinery)

| 'ikamu | Inoa | Qty |

| 1.1 | Extruder | ʻelua pūʻulu |

| 1.2 | Mold | hoʻokahi hoʻonohonoho |

| 1.3 | ʻĀpana Hoʻoponopono | hoʻokahi hoʻonohonoho |

| 1.4 | Mīkini hoʻokuʻu | hoʻokahi hoʻonohonoho |

| 1.5 | Alahaka hooluolu | hoʻokahi hoʻonohonoho |

| 1.6 | Cuuter | hoʻokahi hoʻonohonoho |

ʻO ka mīkini hana puka puka PP

Hoʻolālā maikaʻi ʻia ka laina hana extrusion extrusion o ka hale PP hale e kā mākou hui e hoʻomoʻa a hoʻoheheʻe i ka ʻenehana extrusion holomua ʻē aʻe a me ka hana hou kūʻokoʻa.Hiki ke hana ʻia ka mānoanoa o ka pā i 8-18mm, a hiki ke hoʻololi ʻia ka laulā pā e like me nā koi o ka mea kūʻai aku o 915mm-1220mm.He maʻemaʻe a maʻemaʻe kona papa hana., Ke kuhi liʻiliʻi liʻiliʻi, me ke kui, ka hoʻolālā ʻana, ka pale ʻana i ka corrosion, ka pale ahi a me nā pono ʻē aʻe he nui.

PP Hollow Building Building Template Board Extrusion Line PP Hollow Formwork Board Extruder Making Machine

Nā pono

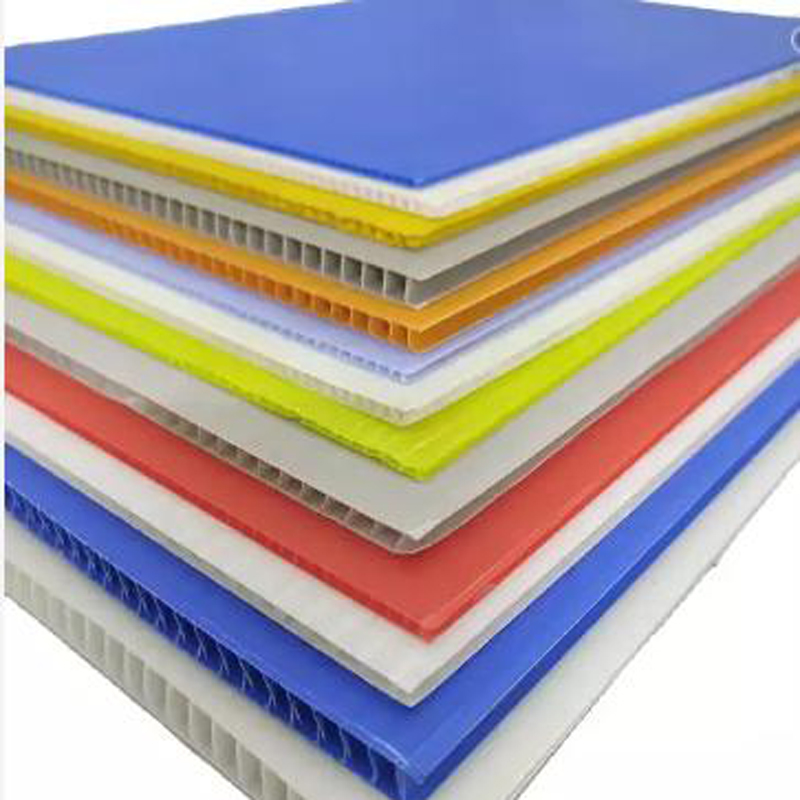

1. ʻO ke kaumaha māmā, ka ikaika kiʻekiʻe, ka paʻakikī kiʻekiʻe, ke kū'ē i ka hopena, ke kū'ē kū'ē.

2. He maʻemaʻe, ʻālohilohi a maʻemaʻe ka ʻili; He maikaʻi ka hoʻopaʻa ʻana a me ka hoʻokumu ʻana no ka mīkini hana pp hollow sheet.

3. ʻAʻohe absorption o ka makū, ʻaʻohe deformation, ʻaʻohe mildew; Long-term immersion stratification i loko o ka wai, ʻaʻohe ʻōhū, paʻa ka nui o ka lau, kūpono no ka lalo o ka honua a me ka dampenvironment.

4. Ka paakiki maikai.Hiki ke hoʻohana ʻia ka mīkini hana pp hollow sheet e like me ka cambered special-shaped formwork.

5. Acid a me alkali kū'ē, corrosion kū'ē;He kūpono loa ka mīkini hana pp hollow sheet no ka noi ʻenekinia ma nā wahi kahakai, koʻu, a me ke kai.ʻAʻole pono ka mīkini hana hollow sheet pp i ka mālama mālama ʻana i ka hoʻohana ʻana a me ka mālama ʻana i ka formwork, ʻaʻole ia e hoʻohaumia i ka ʻili ʻili.6. ʻO ka manawa hiki ke hoʻohana hou ʻia no ka pp hollow sheet making machine hiki ke piʻi ma mua o 60 mau manawa, lōʻihi ke ola lawelawe.

7. Hiki ke hana hou ʻia nā mea ʻōpala a hana hou ʻia, me ka hoʻohana piha ʻana i nā mea ʻōpala.Hiki i kēia waiwai ke hoʻemi nui i ke kumu kūʻai o ka papahana i hoʻohālikelike ʻia me ka hana lāʻau a me ka hana ʻohe.

8. Ka mālama ʻana i ke kaiapuni a me ka mālama ʻana i ka ikehu, ʻaʻohe pollution.ʻAʻohe kinoea ʻawaʻawa a ʻino paha.

9. Demould maʻalahi.ʻAʻole pono e hoʻokuʻu i ka mea hoʻokuʻu, paʻi wale, e hāʻule ke kumu kūʻai o ka plywood formwork.E hoʻopōkole i nā hola hana a e wikiwiki i ka papa hana kūkulu pono.

10. Maʻalahi e hana.Loaʻa ka ʻeli, ka wili a me ke kui.Hiki ke hoʻohui ʻia ka mīkini hana pp hollow sheet ma ka vertically a horizontally optionally.

11. Maʻalahi e wehe.He mea maʻalahi ka wehe ʻana, wikiwiki a palekana, a maʻalahi hoʻi ke kākoʻo ʻana, ʻoi aku ka maikaʻi o ka hoʻonohonoho ʻana, hoʻomaikaʻi maikaʻi i ka papa hana.

Manaʻo ʻenehana nui

| Hoʻohālike | SJ120 | SJ150 |

| Mea waiwai | ʻO PP i hoʻololi ʻia | ʻO PP i hoʻololi ʻia |

| Laulā huahana | 915/1220mm | 915/1220,915×2 |

| Mānoanoa huahana | 15-20mm | 15-20mm |

| Hōʻike kikoʻī Extruder | 120/3575/35 | 150/3590/35 |

| Kaha (Max.) | 350-450kg/h | 500-600kg/h |

ʻO ka papa hoʻohālike PP kūkulu hale formwork PP hollow board extrusion

PLASTIC PE PP hoʻohālike kūkulu hale formwork extrusion mīkini

ʻO ka laina hana hana formwork PE PP kūkulu hale

PE PP plastic formwork papa hana mīkini

HANA KIEKIE

HOOLAHA IKE LOA

KUMU KUPONO

I. Hoolauna nui

Ke lawe mai nei i ka ʻenehana holomua honua, i hui pū ʻia me kā mākou ʻike kūpono a me nā koi o ka home, ua hoʻolālā ʻia kēia laina hana e mākou iho a hoʻohana ʻia e hana i ka pepa palaka, e like me nā koi o nā mea kūʻai aku, hiki iā ia ke hana PVC, PP, PE, PS, ABS, pc, etc.

| kumu hoʻohālike | 915/1220 | |

| Mea kūpono |

| PP/PE |

| Max .ākea o ka huahana | mm | 915/1220 |

| Mānoanoa o ka huahana | mm | 16/18 |

| Ka mana extruder | Kg/h | 300-500 |

| Hiki ke kau ʻia (kokoke) | kw | 350 |

| Ana (L*W*H)(kokoke) | m | 35*2.5*2 |

| Kaumaha nui (koko) | t | 10 |